In your shipment integration between inventory cloud and the 3PL system, some shipment confirmation messages have errored.

How do you manage these pending transactions?

While performing a physical inventory count, you find that tags have not been generated for some of the items.

What action is recommended?

Your customer wants to track and approve inventory transactions between two inventory organizations handling high value goods.

What are the two types of inventory transactions recommended?

Your consumption advice frequency is weekly and the billing cycle closing date is November 7, 2022. What happens when the Create Consumption Advice process is run on November 10, 2022?

Steve, your warehouse manager, created a lot for an item by mistake. He is unable to disable this lot from the Manage Lots task.What could be the reason?

An organization uses min-max planned items to generate movement requests automatically where the item's replenishment source is another subinventory. In this case, the min-max process should automatically generate a move request but it doesn't happen.

What is the reason?

Inventory organization M1 has:

Nettable Quantity On-hand = 24

Open Supply Quantity = 51 with all supply within the supply cutoff date

Open Reserved Sales Order Quantity = 90 with all demand within the cutoff date

Open Unreserved Sales Order Quantity = 10

Min-max Minimum Quantity = 100

Min-max Maximum Quantity = 500

Min-max planning report is run for organization level with Yes specified for the Net Reserved Orders parameter.

What will be Total Available Quantity and Reorder Quantity calculated?

Your client has configured min-max planning for inventory replenishment and has not implemented Oracle Fusion Cloud Manufacturing and Supply Chain Materials Management.

How do you ensure purchase requisitions are generated for inventory replenishment?

Which two actions can be performed from the Supply Chain Orchestration work area?S

Back-to-Back Supply Creation Flows

You can set up Oracle Fusion Cloud applications that support back-to-back fulfillment to trigger supply creations flows (buy, make, transfer, and on hand) after a sales order is entered and scheduled.

Each variant of the back-to-back flow differs in the supply document that's created and the supply execution application in which the document is created. Depending on the source of the item, supply is provided from manufacturing, procurement, or inventory. Then, after the supply is received into the fulfillment warehouse, the back-to-back order is ready for shipment to your customer.

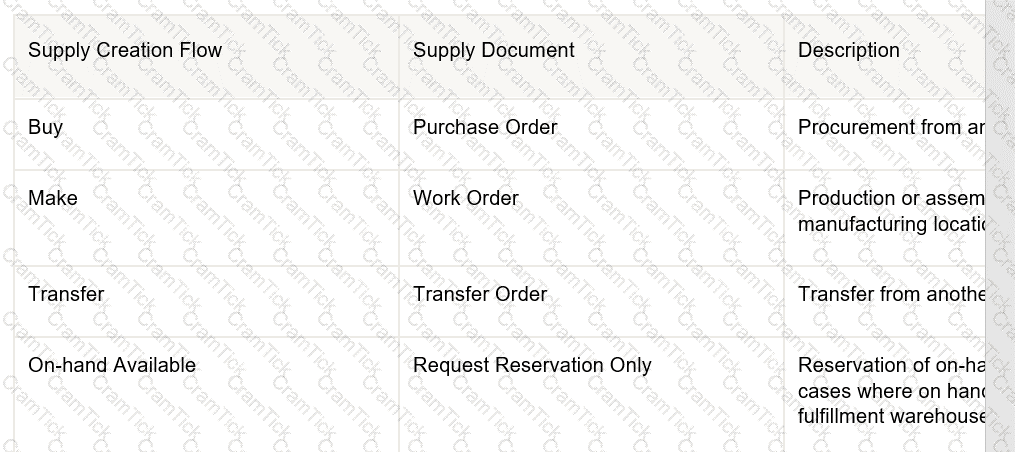

The following table describes the supply creation flows and associated supply document supported for each flow when using back-to-back fulfillment.

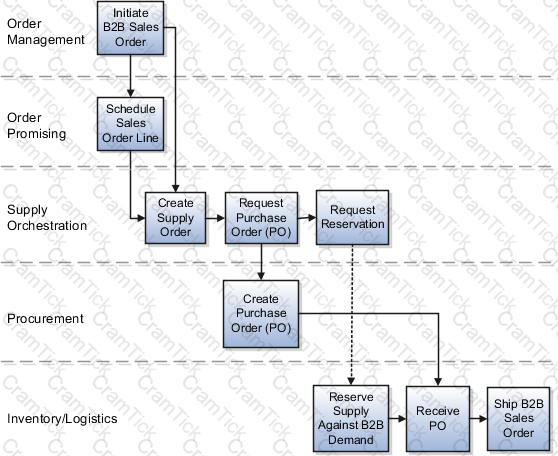

Back-to-Back Supply Creation Buy Flow

The supply document for a back-to-back buy flow is a purchase order. Based on supply recommendations from Oracle Global Order Promising, a purchase order is created and reserved against the sales order. When the purchase order is received by the supplier, on hand is created to ship out the back-to-back sales order.

The following figure shows the back-to-back supply creation buy flow.

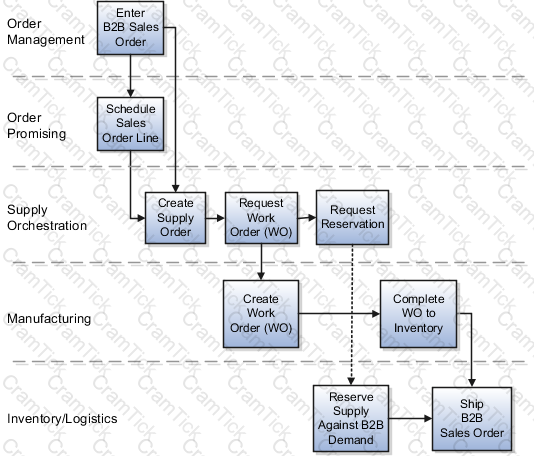

Back-to-Back Supply Creation Make Flow

The supply document for a back-to-back make flow is a work order. As soon as the work order is created in Oracle Fusion Cloud Manufacturing, it's tied to the back-to-back sales order in the form of a reservation in inventory. The work order goes through the regular production process and the work order completion transaction issues finished goods to inventory.

Note: Back-to-back flow is currently supported for only discrete manufacturing.

The following figure shows the back-to-back supply creation make flow.

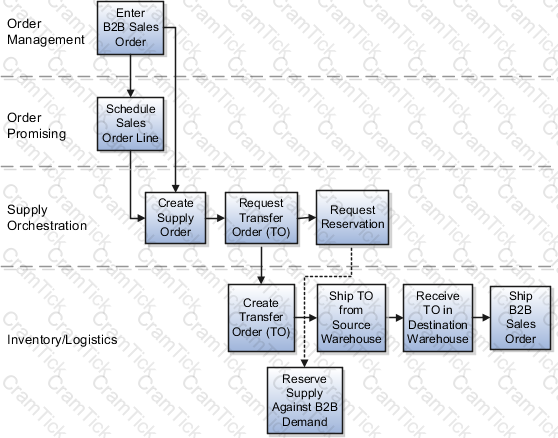

Back-to-Back Supply Creation Transfer Flow

The supply document for a back-to-back transfer flow is a transfer order. The transfer order is created in inventory and reserved against the back-to-back sales order. When the transfer order is ready to be fulfilled, an interorganization shipment moves goods from the source organization to the destination organization. An interorganization receipt in the destination organization (which is also the fulfillment warehouse on the back-to-back sales order) creates on hand to fulfill the sales order.

The following figure shows the back-to-back supply creation transfer flow.

Set Up Back-to-Back Transfer Flow

The topic explains what you need to do for setting up back-to-back transfer flow.

In the Oracle Product Information Management, ensure that the Item is Back-to-Back enabled.

In Oracle Global Order Promising:

1.Set up a global sourcing rule with Type as Transfer from. Set the organization as the organization requesting the transfer (example, Warehouse 1).

2.Set up a local sourcing rule for the organization (in this example, Warehouse 1) Type as Transfer from, from the organization that has the stock from which the transfer will take place (example, Warehouse 2).

3.Set up an ATP rule with the Promising Mode as Supply chain availability search.

4.Ensure that the Supply chain availability search attributes are enabled according to your requirements. For example, you might want the application to search components and resources to include on-hand or in-transit Supply Types or fulfillment lines Demand Types.

5.Set the ATP Rule Assignment as required.

6.Set the sourcing assignments for the sourcing rules that you defined in steps 1 and 2.

7.Ensure that the assignment level used for the global sourcing rule doesn't include any Organization.

8.Refresh and restart the Order Promising Server for ATP Rules and Sourcing.

With this setup:

•The global rule is used to source the item from Warehouse 1 if there is stock available to reserve.

•If there's no stock on hand, Global Order Promising uses the local rule to transfer the item from Warehouse 2 to Warehouse 1.

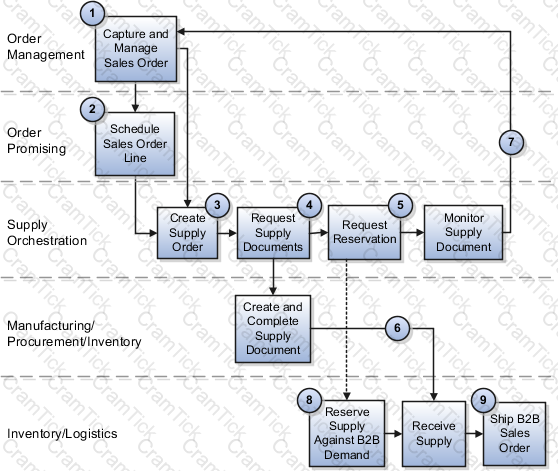

How Back-to-Back Fulfillment Works

The back-to-back process flow is one in which specific sales order demand triggers supply creation and a link is established between the sales order and the supply.

An organization procures goods from an internal or external supplier or source to a specific warehouse from where you can combine those goods with others to create a single shipment to the customer.

Back-to-back supply processes are similar to regular supply processes that deliver supply to a warehouse except for one difference; the back-to-back supply is always reserved to an order management fulfillment line.

At a high level, you can think of back-to-back fulfillment as a three-step process:

1.Creation of a customer sales order (source of demand).

2.Creation and fulfillment of supply document (source of supply) to the fulfillment warehouse.

3.Shipment of sales order from the fulfillment warehouse to the customer.

However, the back-to-back flow is truly a highly integrated process flow involving several Oracle Fusion Cloud applications. The following figure shows the back-to-back process flow in detail. An explanation for each number follows the figure.

Back to Back fulfillment

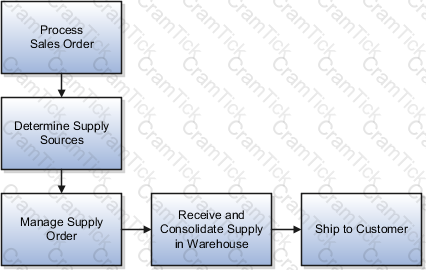

Overview of Back-to-Back Fulfillment

The back-to-back fulfillment process is one in which specific sales order demand triggers supply creation, and a link is established between the sales order and the supply.

Note: Back-to-back flow is currently supported only for discrete manufacturing.

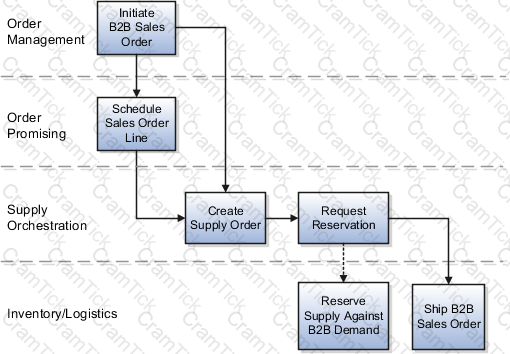

The following figure provides a high-level flow diagram showing the back-to-back supply creation and fulfillment process flow.

Back-to-back fulfillment is where supply is procured and then received at a warehouse only after an order is placed.

The supply is reserved against a sales order until shipping.

This process provides support to create and link supply after a sales order is entered and scheduled, allowing you to reduce your inventory while maintaining the ability to respond to customer demands.

You create supply for a back-to-back order using one or more of the following back-to-back flows:

•Buy: Procurement from an external supplier.

•Make: Production in an internal manufacturing facility (includes in-house manufacturing and contract manufacturing).

•Transfer: Transfer from another warehouse.

•On hand: Reservation of on-hand supply in the fulfillment organization.

Note: For information about back-to-back flows for contract manufacturing, see the Implementing Contract Manufacturing chapter in this guide.

After the supply is received into the fulfillment warehouse, the back-to-back order is ready for shipment to the customer.

Back-to-Back Supply Creation On-Hand Flow

The back-to-back on-hand available (ATP) flow is the simplest in terms of the number of steps that constitute the flow. This flow occurs where on hand supply is available in the fulfillment warehouse for the ordered back-to-back item at the time of order promising. Because on-hand goods already exist in the form of on hand, Oracle Supply Chain Orchestration directly sends a request to reserve the on hand quantity against the back-to-back sales order. You can ship the sales order immediately after the reservation is created.

The following figure shows the back-to-back supply creation on-hand flow.